My home workshop has been built up over many years. It includes woodworking and metal working tools.

My Metal Working Tools Include:

- Grizzly G4003G Lathe: When the original motor burned up I decided to replace it with a 3 phase motor and a VFD. G4003 VFD Conversion

- Precision Mathews PM30-MV Mill: Made this a CNC machine. PM30-MV Mill Conversion to CNC

- Harbor Freight 4X6 Horizontal Band Saw.

- Grizzly Model H7760 combination 6″ grinder and belt sander

My Woodworking Tools Include:

- Ridgid 10″ Table Saw: I added a router table on the right end of the table set up to mount a Bosch router with interchangeable insert plates. I also added a custom out feed table.

- Ridgid 12″ Radial Arm Saw. CMT blades are the best I have found.

- The Workbench is 4′ wide by 14′ long.

- Ridgid Planer.

- Harbor Freight (Central Machinery) Drill Press: Built a custom table with fence – useful to mount stop blocks, clamps, etc. Also has wings on the end to support larger work.

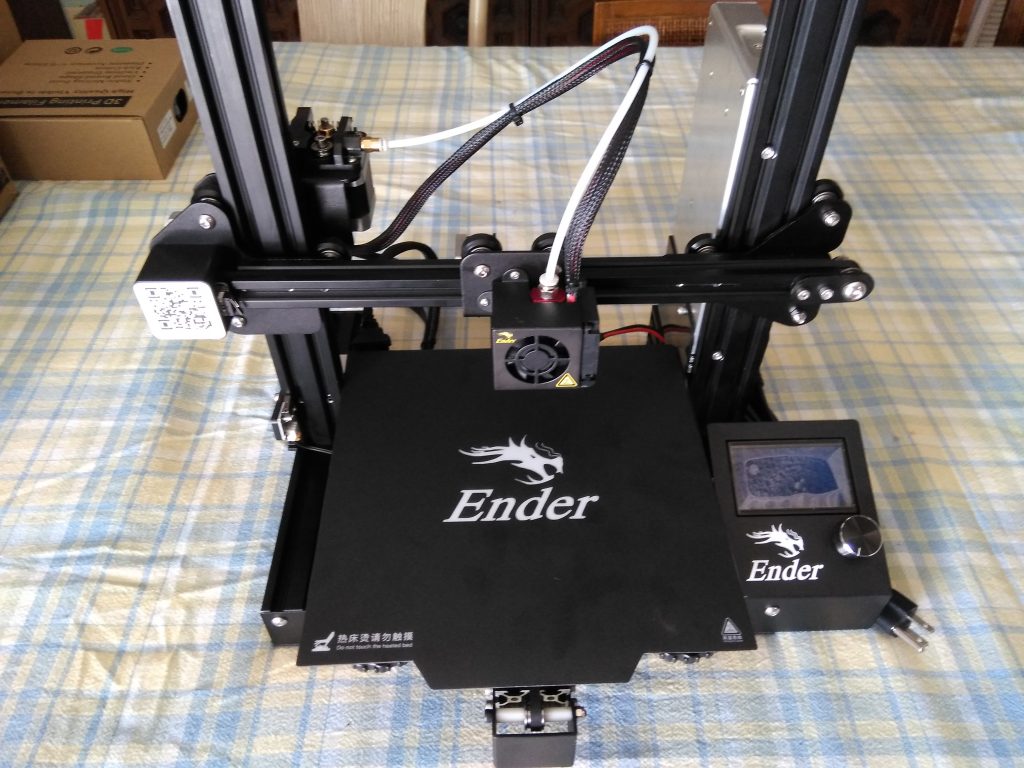

I use a Creality Ender 3 Pro 3D printer. Creality Ender 3 Pro 3D Printer

My other interests include astronomy:

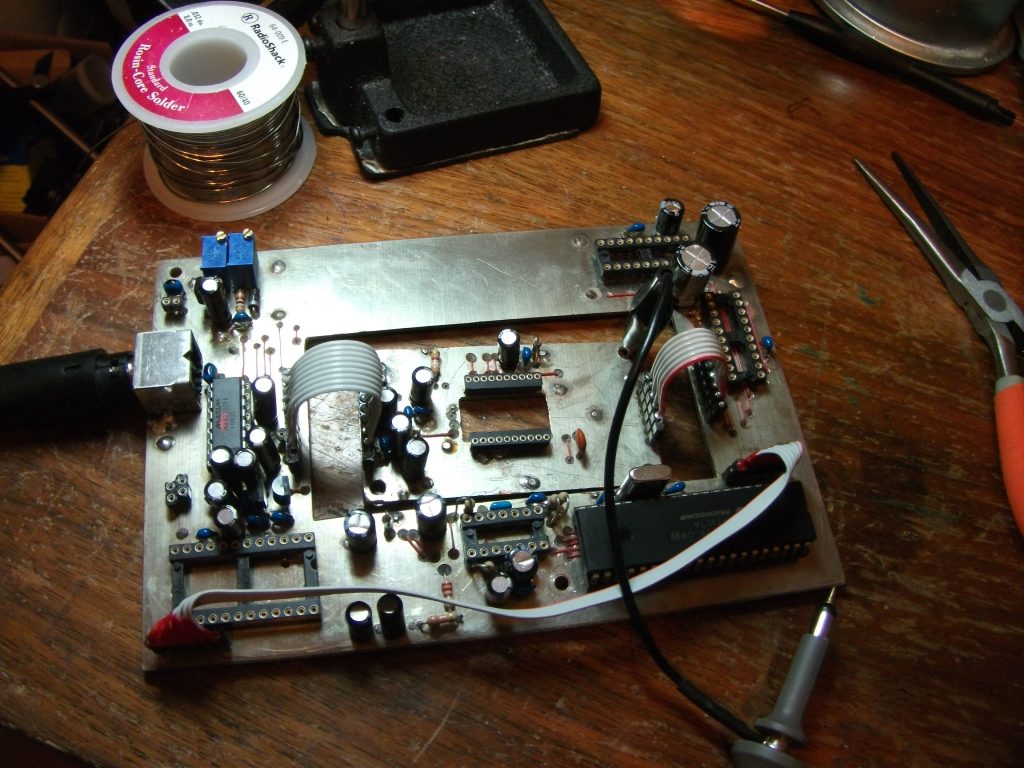

Repair of a Meade LX200 10″ with a homemade telescope control system. Telescope – Meade 10″

A homemade astronomical camera. UAI-CCD Camera Stuff

A webcam modified for long exposures. SP900NC Webcam

Pillar Tool Construction. Pillar Tool Construction

Safety:

Safety is the single most important thing in any shop. All the tools in the shop are inherently dangerous and capable of inflicting all kinds of injuries. Make sure you are wearing personal protective equipment (PPE) appropriate for your equipment and to the task at hand. Learn to use all your equipment safely. Read all the safety material that comes with each machine that you use.

Here are some of the safety items I use in my shop:

Safety glasses (all the time), face shield (used with safety glasses on the grinder, lathe and mill), hearing protection (when using the planner, etc.), full face respirator when spraying paint or lacquer, guards on all equipment – see the guards I made for my bench grinder for the various wheels I use.

No long sleeve shirts, no rings, watches or jewelry, gloves only when appropriate: cleaning up swarf , welding, not when operating lathe or mill or most other machine tools. Type of glove for the job is important.

Electrical: never work on a live electrical panel. If you must power a panel to trouble shoot with a multi-meter (for example) dress with appropriate PPE for the voltage in the panel including gloves and full face shield – see OSHA guidelines. I know of someone who was attempting to measure 480V/3phase power with a handheld meter and accidentally shorted line to ground with the tip of his probe. He was thrown out of the small room he was in an had burns on one side of his face and his arm – he was in the hospital for 3 months. Arc-flash accidents are no joke. Any time you make change to an electrical panel make sure the cover is completely screwed on and do not stand in front of the panel the first time it is powered up.

My pictures and video’s may show equipment without guards in place to view the operation clearly or assemblies in various stages of completion.

Carbide end mills can explode with too fast a feed and/or too deep a cut.

Swarf can be picked up by a chuck and spun around dangerously.

The above is not a comprehensive of safety issues. Please do your own research and operate safely.

My drawings, designs, setups and information that I am providing on this site are provided for your enjoyment and probably contain errors and omissions. There are no guarantees or warranties of fitness for any particular use or purpose. Setups and modifications shown may be unsafe. Designs and modifications I have shown to machinery, equipment, webcam’s and other stuff may break the item beyond repair. Use the material presented on this website at your own risk.