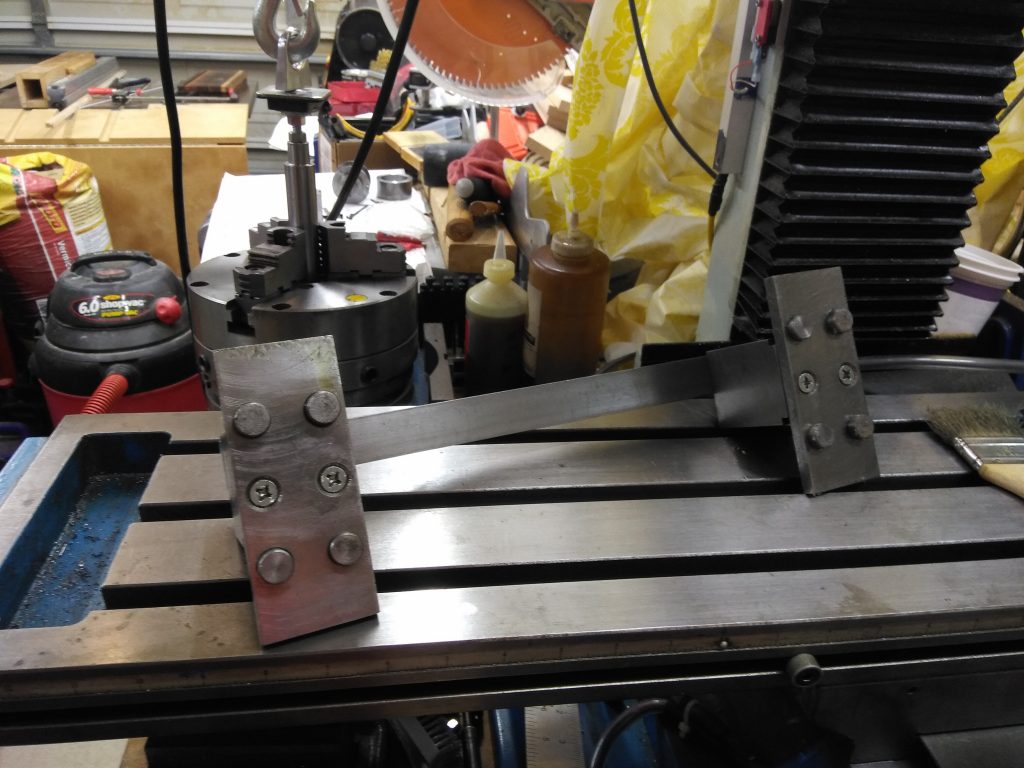

This is my Vice Alignment Tool.

I found it at:

https://haythornthwaite.com/vice%20align.html

Thanks to haythornwaite for a great idea.

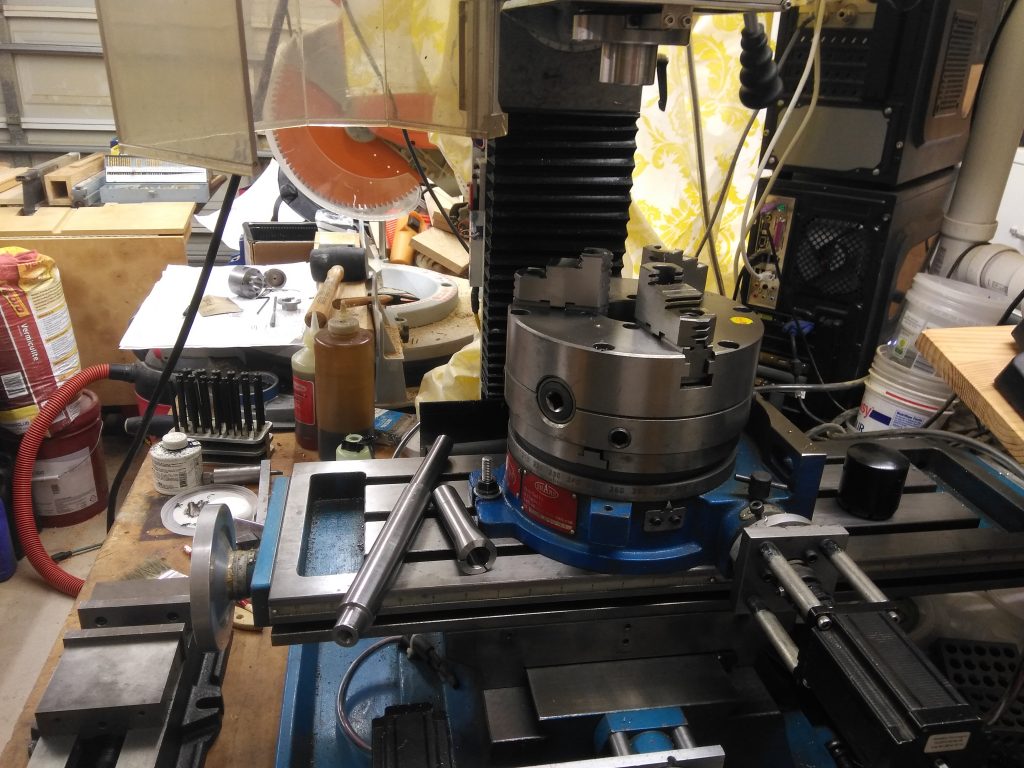

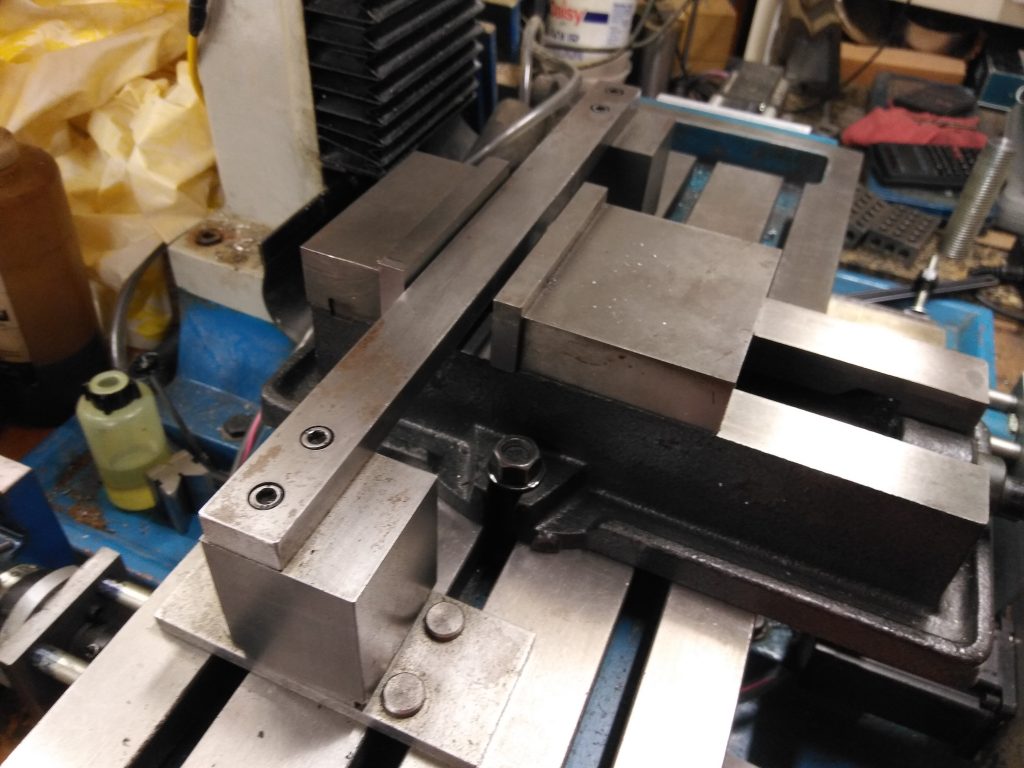

This is my Rotary Table:

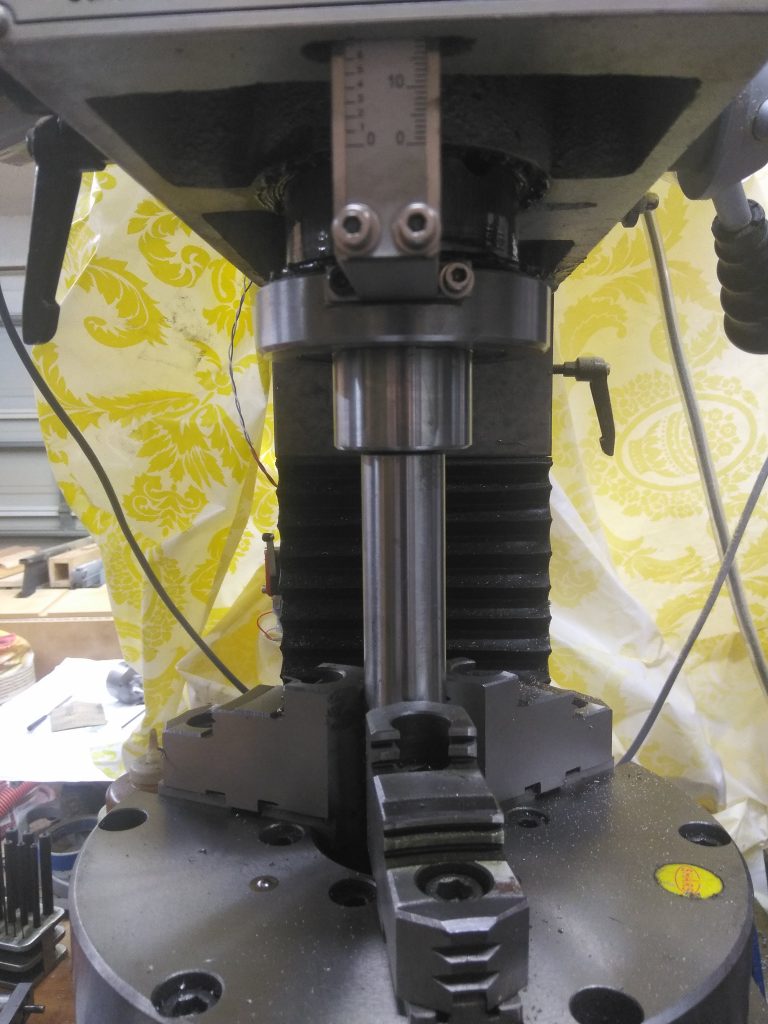

I purchased a Shars 8″ Precision Horizontal and Vertical Rotary Table. I also purchased an Shars 8″ 3 jaw chuck that can be mounted on the rotary table or lathe. The chuck came with a centering faceplate that allows for an extremely precise alignment. I’ve achieved .0003 runout with just a few minuets effort.

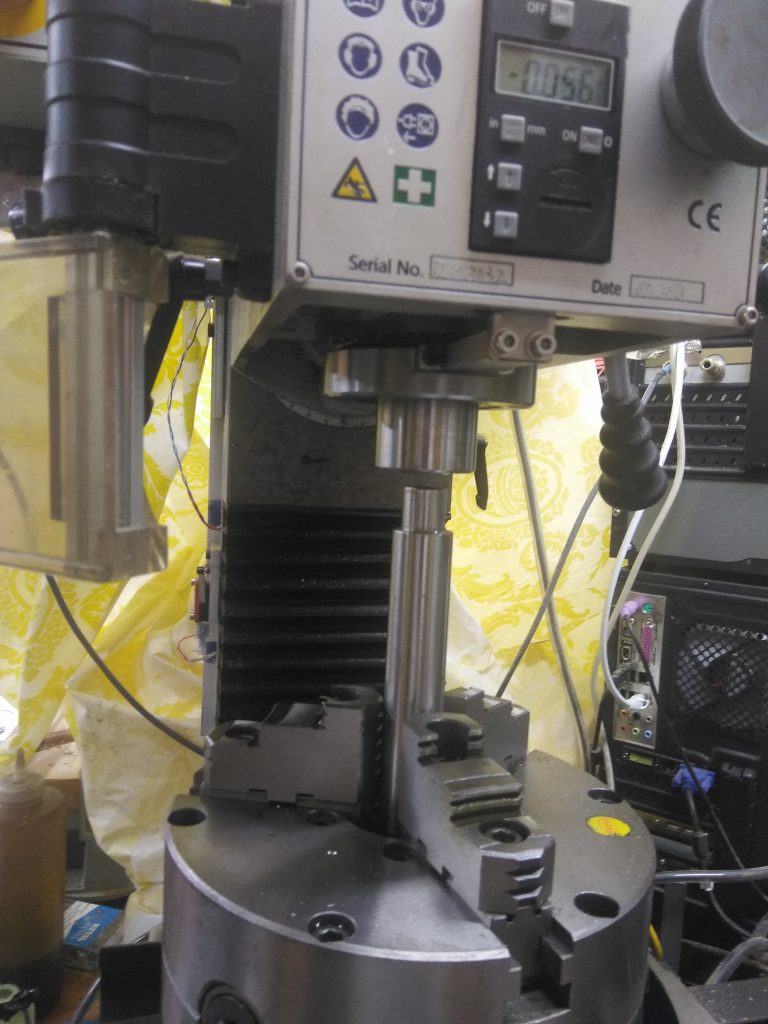

Move the table until the shaft is centered on the collet.

When the collet slides onto the shaft the table is centered.

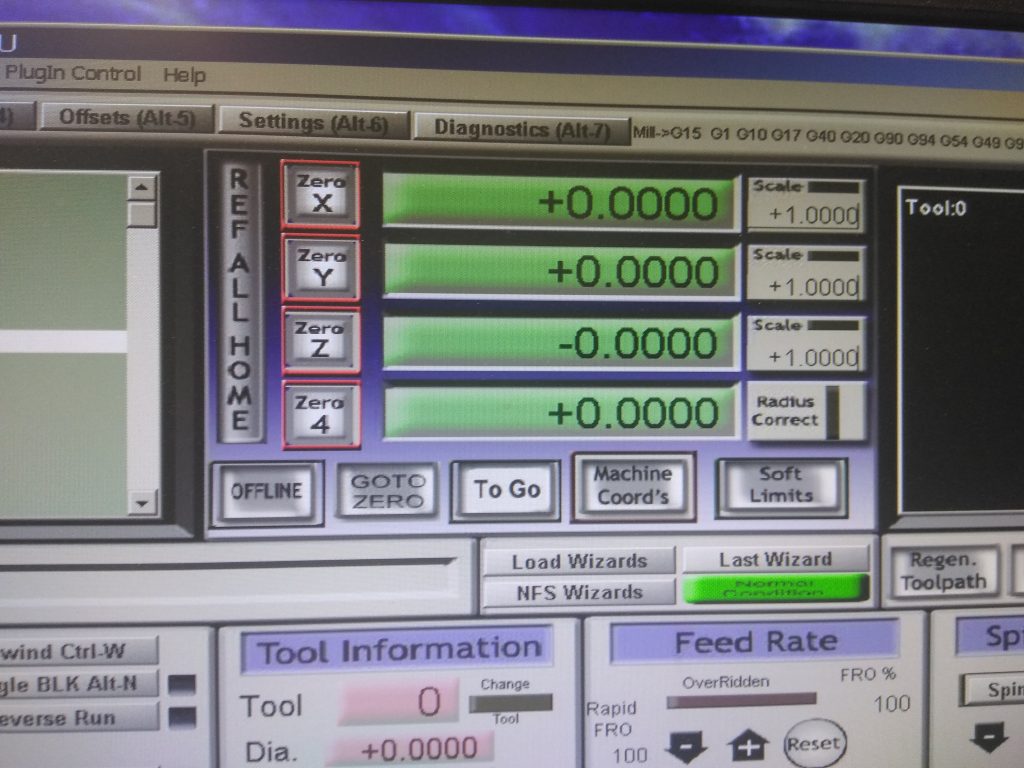

Then zero the x,y and a axis.

Getting ready to center the rotary table under the spindle. I use a 3/4″ collet in the spindle and a shaft with a 3/4″ turned end held the the jaws. Notice the taper on the front end of the shaft to fit the rotary table.

Once the chuck is centered on the table and the table is centered on the spindle offsets can easily be dialed in to drill holes on any radius (I typically use the x axis for any offsets.

This is my Speed Increaser for the mill:

My mill top speed is just under 2000 rpm. This is fine for most work. But when i use bits 1/8″ or smaller (like for engraving) then 2000 rpm is too slow. This is a Hemingway Kit. I really like their kits and you will see many of their kits on this site. This project is almost complete – need to add the shaft and bar that holds the body to the spindle. This speed increaser is a 1:3 so my top speed for these tiny bits will be just under 6000 rpm. I will keep you posted on how this works out.

ER-11 Collet holder cut down and threaded

Assembled Speed Increaser

Parts

Speed increaser ring gear

Sun gear, planet gear and housing.

.